From RBN Energy's piece on hydrogen today:

We’ll begin with the joint effort by Wisconsin, Minnesota, North Dakota and Montana — the last of which is actually part of PADD 4 (Rockies) — to develop what we’ll refer to as the Great Plains Hydrogen Hub. Its primary element would be a large SMR- or ATR-based hydrogen production facility at what is now Dakota Gasification Co.’s Great Plains Synfuels Plant near Beulah, ND. (Dakota Gasification is a for-profit subsidiary of Basin Electric Power Cooperative.) The plant, which was completed in 1984, each day converts about 18,000 tons of locally mined lignite coal into 150 MMcf of synthetic natural gas (syngas) and other products, including urea, anhydrous ammonia and tar oil. The facility (see photo below) captures about 50% of the CO2 generated during the coal-gasification process. The 8,000 metric tons (MT) a day of captured CO2 then is transported by pipeline more than 200 miles north to the province of Saskatchewan, where it is used in enhanced oil recovery (EOR) in the Weyburn and Midale fields.

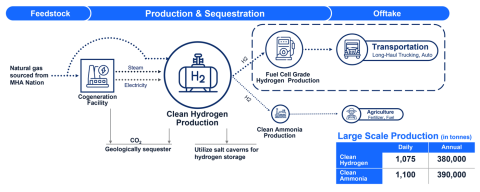

In August 2021, a partnership of Bakken Energy, a privately held company, and Mitsubishi Power Americas reached an agreement to acquire the Great Plains Synfuels Plant from Basin Electric Power Cooperative and redevelop it into a clean hydrogen production facility. That site, which Bakken Energy and Mitsubishi expect will be online as soon as 2027, will use ATR to break down natural gas into hydrogen and CO2, capturing 95% of the resulting CO2 in the process. As shown (from left to right) in the Figure 1 flow chart below:

- Natural gas for the operations will be sourced from reserves owned by the Mandan, Hidatsa and Arikara (MHA) Nation at the nearby Fort Berthold Indian Reservation (within the Bakken Shale region).

- The natural gas will fuel an onsite cogeneration plant to produce steam and electricity for the ATR process (labeled “Clean Hydrogen Production”).

- The CO2 generated will be piped (as it is now) to Saskatchewan for use in EOR.

- The resulting low-carbon hydrogen (H2) will be used in hydrogen fuel cells in long-haul trucking and automobiles and to produce clean ammonia for subsequent use in fertilizer or power production.

- Salt caverns at the site will be used for hydrogen storage.

- Clean hydrogen production is expected to average 1,075 MT/day and 380,000 MT/year and clean ammonia production is expected to average 1,100 MT/day and 390,000 MT/year.

Figure 1. Clean Hydrogen/Clean Ammonia Production Process. Source: Bakken Energy

The thinking behind the proposed redevelopment of the Great Plains Synfuels Plant into a clean hydrogen facility is that at least some of the existing equipment there could be repurposed and — more important — the existing CO2 pipeline and EOR-related offtakers would eliminate the need to develop new CCS infrastructure. Bakken Energy has asserted that the project will produce clean hydrogen for less than $1/kilogram, a 2030 goal of the DOE and the Biden administration. The February 2022 natural-gas-supply agreement that Bakken Energy and Mitsubishi reached with the MHA Nation also may give the proposal a leg up in that the DOE has said it will look favorably upon projects that involve and benefit traditionally disadvantaged groups, including Native Americans.

While the Great Plains Hydrogen Hub is founded on the Bakken Energy/Mitsubishi plan for redeveloping the Great Plains Synfuels Plant, the hub also is likely to include a number of smaller clean hydrogen production facilities in Wisconsin and Minnesota (and maybe North Dakota and Montana too). These facilities would use wind power or other renewable energy to run electrolyzers, which break down water into hydrogen and oxygen, generating no CO2 in the process. Clean hydrogen from the electrolyzers could be used for any number of purposes, including the production of fuel cells or blending into natural gas.